... the other way.

ECOCER2

ECOGRAPHS LATEST PRODUCT

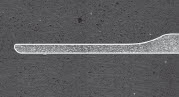

For ECOCER2 we use strip steel of highest quality, which is partially coated with a protective layer on the area coming in contact with the cylinder. Compared with our conventional ECOCER this protective layer undergoes a special finish, whereby the structural conditions are changed in

such a way that it can take up an increased amount of ink. The higher take up of ink alters the tribological features and improves the lubrication in the long term. Combined with the high hardness and a good ductility of the coating we achieve an extremely high wear resistance.

The modified structural conditions optimise the wear resistance.

To summarize, the following improvements

are achieved when using ECOCER2:

- reduced adhesion wear

- increased cylinder running times

due to reduced chrome wear

- reduced streaking

- significant reduction of defects in

print image and hazing (fogging)

- much cleaner print out

- longer running times

- significantly less maculation

- very good and continuously high

quality of your printing products

Ready-to-use with a variety of machines and inks as well as print materials, ECOCER2 is a valuable addition to our range of products and consequently to your production.

ECOCER2 enables you to increase standards and achieve highest printing results.

ECOCER2 IS AVAILABLE IN THE FOLLOWING SIZES

MATERIAL

THICKNESS

SHAPE

OF LAMELLA

THICKNESS

OF LAMELLA

WIDTH

OF LAMELLA

0.150 - 0.300mm

Parallel, bevel,

long bevel

0.070- 0.250mm

0.8 / 1.0 / 1.5 /

1.7mm

News